The connection cable of all TRUEBNER sensors has a particularly robust polyurethane sheath (PUR), the outer diameter is approx. 3.8 mm, the inner structure consists of 4 flexible strands with a cross-section of 4 x 0.25 mm².

When extending the sensor cables, identical or equivalent cable should be used.

A durable, robust and, when properly executed, waterproof cable extension shall be made exclusively as follows:

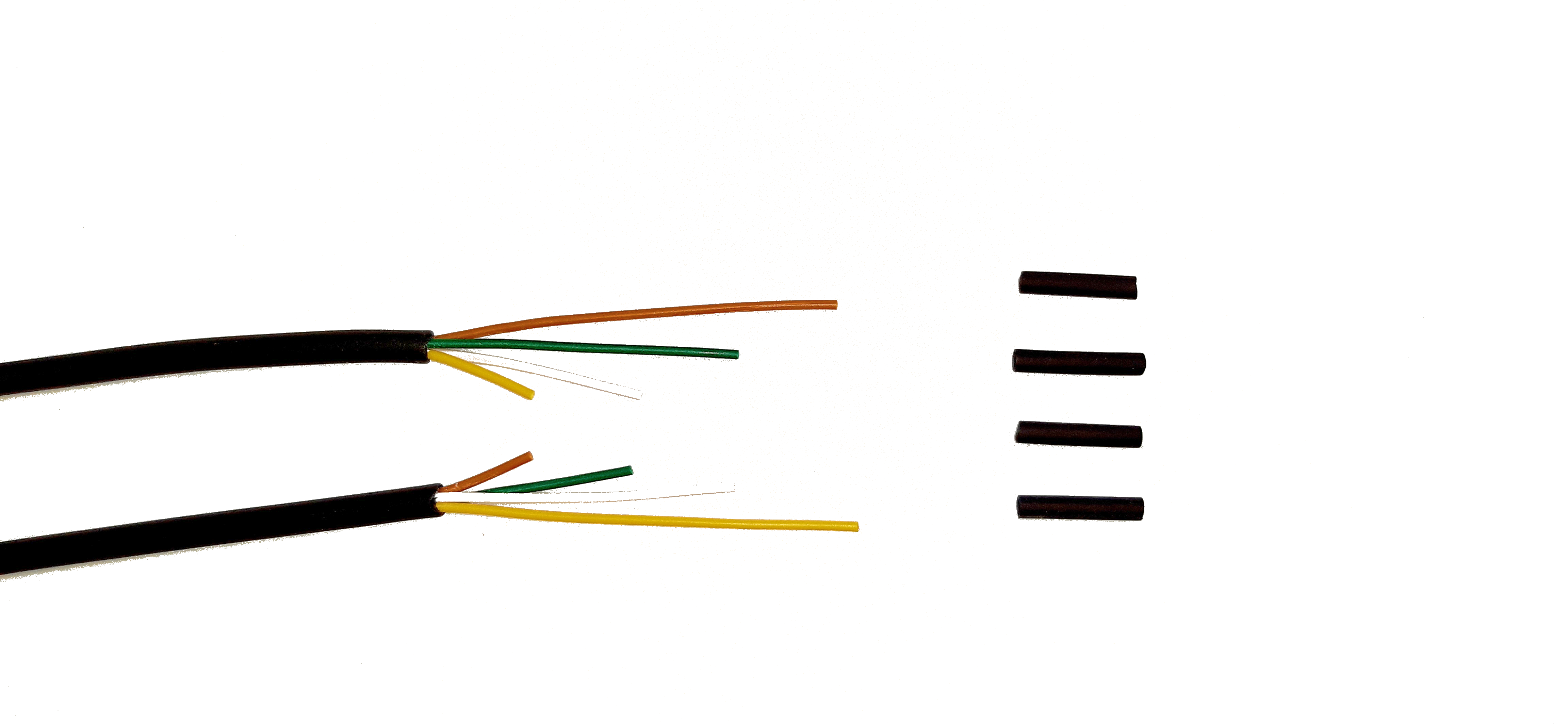

Strip both cable ends over a length of approx. 5 cm. Carefully cut open the black sheathing without damaging the insulation of the inner wires. Shorten the length of the inner wires in opposite directions as shown. To do this, prepare 4 short pieces of heat shrink tubing with a length of approx. 1-1.5 cm.

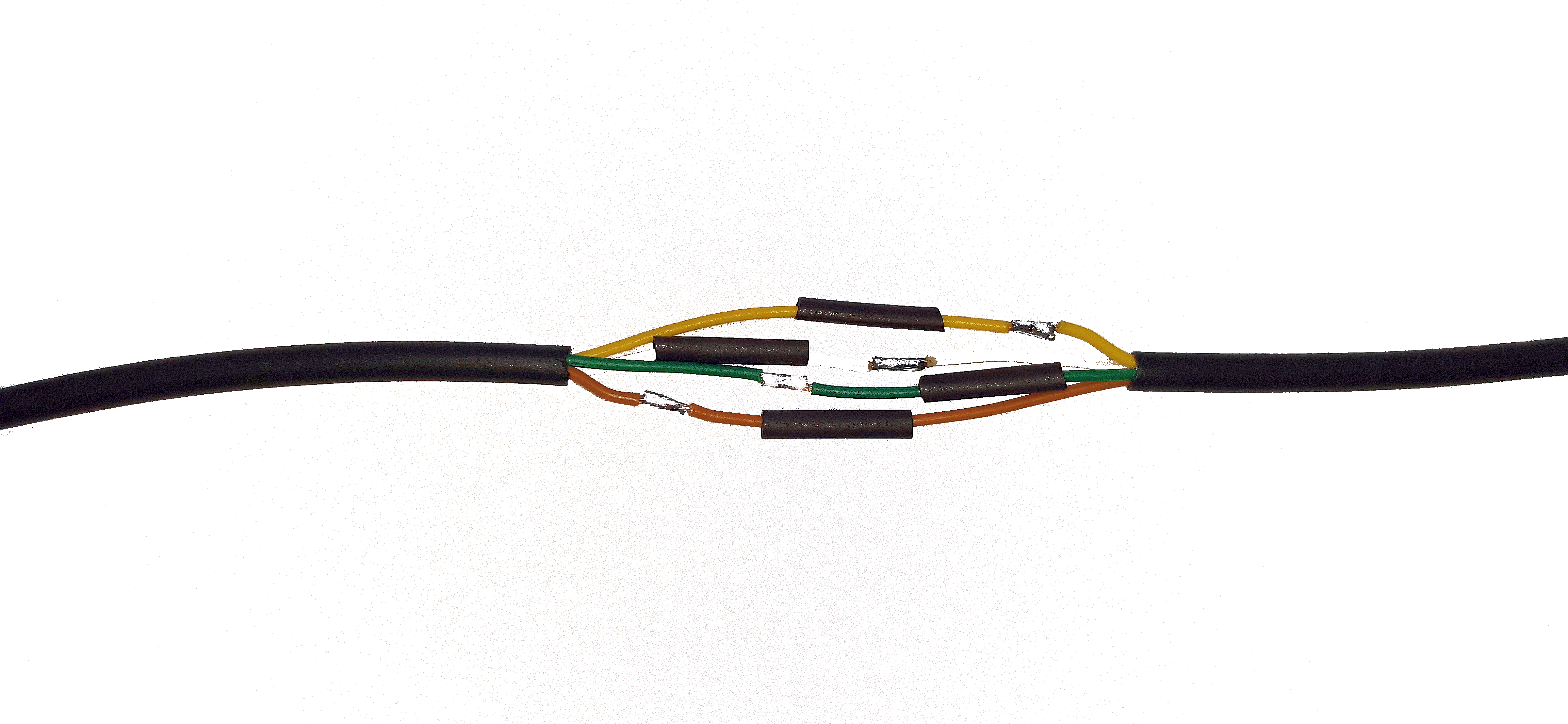

Step 2:

Step 2:Solder the cable ends together as shown. Before soldering, slide the pieces of heat shrink tubing over the cores. Only a cleanly made soldered connection is corrosion-resistant in the long term. Clamp, crimp and screw connections are not suitable.

Step 3:

Step 3:After soldering, push the shrink tubing onto the individual solder joints and shrink with hot air. Heat shrink tubing with an internal layer of hotmelt adhesive is particularly recommended here, as it already covers the individual solder joints in a watertight manner.

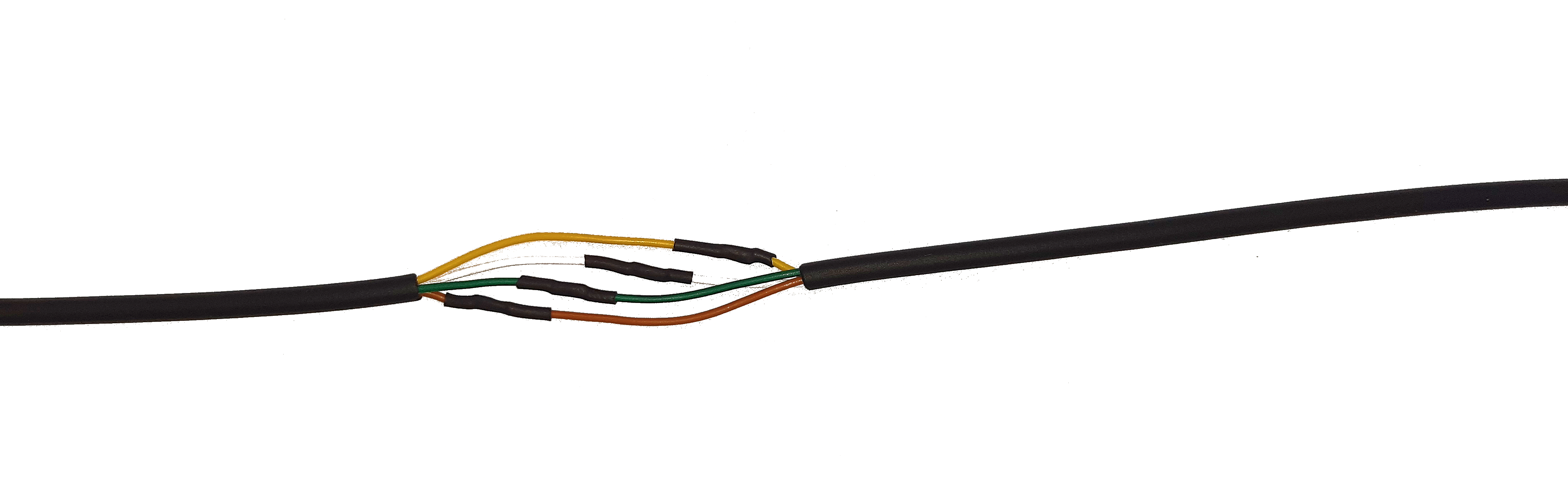

Step 4:

Step 4:Then generously cover the joint with a 25 cm length of heat shrink tubing. The length of 25 cm is necessary to achieve sufficient tensile strength in the longitudinal direction on the one hand and to guarantee an absolutely watertight connection on the other. Care must be taken to ensure that the heat shrink tubing used contains hot melt adhesive and is suitable for use in the ground. A shrink hose with a diameter of 8 mm before and 2 mm after shrinking is ideal (source of supply: e.g. Voelkner-Elektronik Versand, part no.: X774691).

Step 5:

Step 5:When shrinking with hot air, make sure that the shrink tubing is heated evenly and that the adhesive layer on the inside melts. It is essential to observe the maximum permissible temperature of the shrink tubing manufacturer. The following figure shows a finished connection.